Why a Sustainable Supply Chain Is Strategic for Companies

Condividi questo post

In 2025, building a sustainable supply chain is no longer optional—it is a strategic necessity to ensure operational resilience, regulatory compliance, and long-term value creation.

Yet, many companies still underestimate the impact of their supply chain on environmental, social, and financial performance.

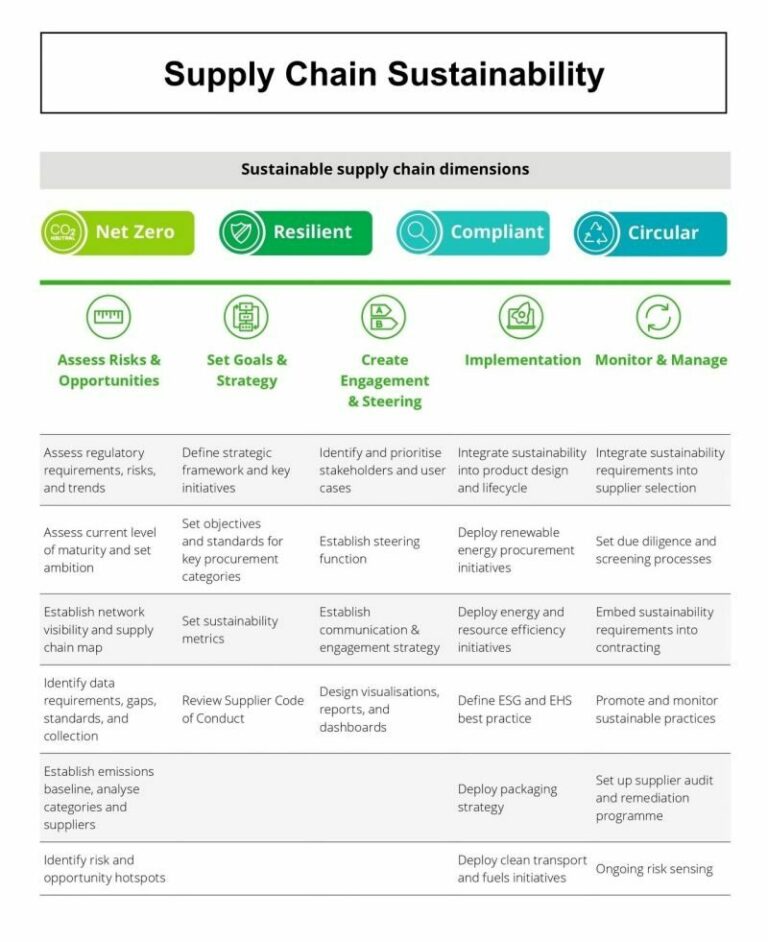

To address this challenge, businesses must integrate four strategic dimensions across five operational steps. This article outlines how to turn sustainability from a vision into an actionable, measurable framework that drives competitive advantage.

The 4 Strategic Pillars of a Sustainable Supply Chain

First and foremost, companies need to focus on these four critical areas:

Net Zero

Systematically reduce Scope 3 emissions across the value chain, aligned with international climate goals.Resilience

Ensure adaptability to regulatory, climatic, and geopolitical disruptions while maintaining business continuity.Regulatory Compliance

Meet evolving ESG regulations—such as CSRD, CSDDD, SFDR, EU Taxonomy, and CBAM—through traceable and verifiable reporting systems.Circularity

Embrace circular economy models by optimizing resource usage, designing sustainable products, and engaging suppliers in regenerative practices.

The 5 Operational Steps to Build a Sustainable Supply Chain

Next, organizations must translate these strategic pillars into actionable processes. Here are the five key steps to consider:

Risk Evaluation

To begin with, ESG risk assessment starts by identifying:

Regulatory trends

Industry benchmark emissions

Supply chain visibility gaps

Data integrity and traceability issues

This process allows companies to quantify exposure, increase ESG maturity, and define targeted investment priorities.

Strategy and ESG Governance

Once insights are gathered, it’s time to develop a solid sustainability strategy by:

Defining ESG KPIs for procurement

Updating supplier codes of conduct

Embedding ESG clauses into contracts

Creating cross-functional sustainability task forces

Therefore, this step operationalizes sustainability, moving it beyond policy into daily decision-making.

Stakeholder Engagement

At the same time, engaging supply chain stakeholders is critical for:

Integrating ESG and EHS standards into operations

Enhancing internal and external transparency

Mitigating reputational and operational risks

In short, a sustainable supply chain is one that is co-created and collaboratively managed.

KPI Implementation

At this stage, sustainability becomes tangible through data. Implementing KPIs allows businesses to:

Monitor supplier performance

Track ESG outcomes across tiers

Detect early signs of risk or non-compliance

Consequently, KPIs serve as the foundation for continuous improvement and informed decision-making.

KPI Monitoring and Management

Finally, ensuring alignment over time requires:

ESG due diligence procedures

Ongoing supplier audits

Contract updates with ESG criteria

Real-time risk detection mechanisms

As a result, sustainability becomes a key lever for supply chain resilience and long-term competitive advantage.

How ecosostenibile.eu Supports Sustainable Supply Chain Management

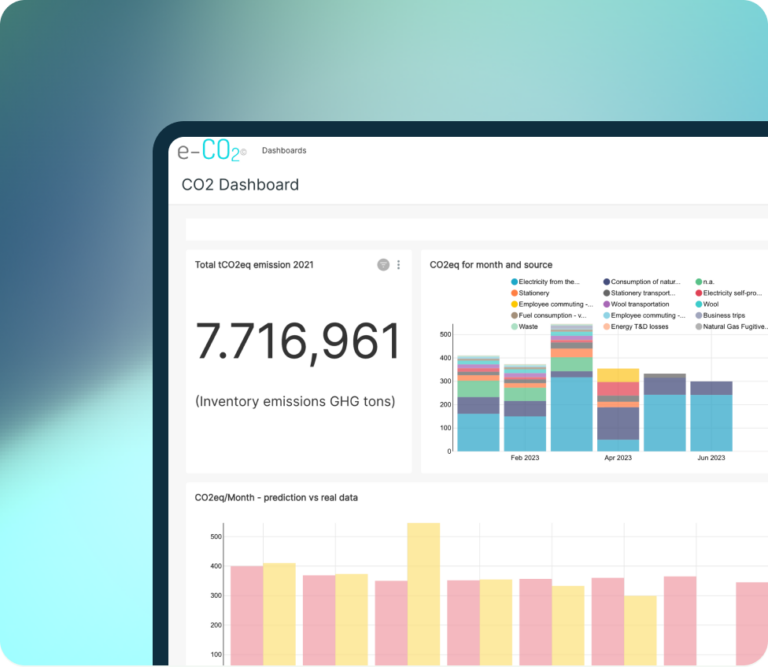

ecosostenibile.eu®, as a certified benefit company, offers an integrated SaaS platform to:

Map and assess ESG supply chain risks

Automate KPI tracking and reporting

Monitor compliance and manage exceptions

Integrate seamlessly with ERP systems and ESG reporting tools

In conclusion, the platform supports companies step-by-step, streamlining operational efforts and increasing the effectiveness of their sustainability strategy.

Christian Sansoni